Electrical Insulated Electrical Safety Gloves are the first line of defense for technicians and electricians who work closely with electrical equipment. Although arc flash suits help to minimize injury, electrical gloves provide critical direct protection. For this reason, a variety of protective glove designs have been developed to ensure that workers can conduct installation, maintenance, and repair of electrical wiring and equipment with minimal risk.

At Burlington Safety Laboratory, safety comes first. We offer a full selection of electrical safety gloves, including rubber gloves, liners, and leather protectors in a variety of safety ratings.

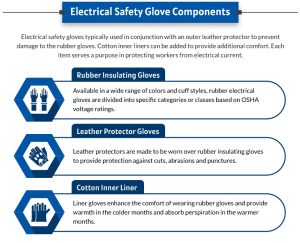

Electrical Safety Glove Components

Electrical safety gloves are typically used in conjunction with an outer leather protector to prevent damage to the rubber gloves. Cotton inner liners can be added to provide additional comfort. Each item serves a purpose in protecting workers from electrical current.

Electrical safety gloves are typically used in conjunction with an outer leather protector to prevent damage to the rubber gloves. Cotton inner liners can be added to provide additional comfort. Each item serves a purpose in protecting workers from electrical current.

- Rubber Insulating Gloves: Available in a wide range of colors and cuff styles, rubber electrical gloves are divided into specific categories or classes based on OSHA voltage ratings.

- Leather Protector Gloves: Leather protectors are made to be worn over rubber insulating gloves to provide protection against cuts, abrasions and punctures.

- Cotton Inner Liner: Liner gloves enhance the comfort of wearing rubber gloves and provide warmth in the colder months and absorb perspiration in the warmer months.

OSHA Ratings for Rubber Insulating Gloves

OSHA has established strict guidelines for rubber insulating glove ratings and usage. Based on ASTM D120 Standard Specifications for Rubber Insulating Gloves, OSHA’s ratings are as follows:

OSHA has established strict guidelines for rubber insulating glove ratings and usage. Based on ASTM D120 Standard Specifications for Rubber Insulating Gloves, OSHA’s ratings are as follows:

- Class 00: Maximum 500V (AC) and 750V (DC)

- Class 0: Maximum 1000V (AC) and 1,500 (DC)

- Class 1: Maximum 7,500V (AC) and 11,250 (DC)

- Class 2: Maximum 17,000V (AC) and 25,500V (DC)

- Class 3: Maximum 26,500V (AC) and 39,750V (DC)

- Class 4: Maximum 36,000V (AC) and 54,000 (DC)

Types of Electrical Safety Gloves

In addition to OSHA ratings, electrical safety gloves are divided into two categories based on material resistance. Type I gloves are typically manufactured from natural rubber and do not exhibit ozone resistance. Type II gloves are generally made from synthetic rubber and are ozone resistant. Only class 00 and class 0 gloves are available in Type I and Type II. All other gloves are made with Type I rubber.

In addition to OSHA ratings, electrical safety gloves are divided into two categories based on material resistance. Type I gloves are typically manufactured from natural rubber and do not exhibit ozone resistance. Type II gloves are generally made from synthetic rubber and are ozone resistant. Only class 00 and class 0 gloves are available in Type I and Type II. All other gloves are made with Type I rubber.

Electrical Safety Glove Designs

Rubber insulating gloves can be divided into several categories based on voltage, cuff style and color.

- Voltage Ratings: Insulated rubber gloves are categorized by the max voltage they can withstand. They are divided into classes with Class 00 being the lowest and Class 4 being the highest.

- Cuff Style: Insulated rubber gloves are available in varying cuff styles including straight cuff, bell cuff and contour cuff. Classes 00, 0 and 1 are only available in straight cuff. Classes 2, 3 and 4 are available in all three cuff styles.

- Glove Color: Insulated rubber gloves are available in a variety of colors with red and black being the most common for the lower classes 00 and 0 and dual color gloves being the most common for all other classes. There is no difference in integrity between the colors, it’s just a personal preference.

High Voltage vs. Low Voltage Gloves

Typically low voltage gloves refer to class 00 and class 0 gloves and high voltage refers to classes 1 through 4. Class 00 and class 0 gloves are available in both Type I and Type II rubber while all other classes are only made with Type 1 natural rubber. The rubber insulating gloves are made with a dipping process to create the necessary thickness (or layers) of rubber to withstand the voltage required for that particular class of glove. Low voltage gloves are thinner while high voltage gloves get thicker with each voltage rating.

Electrical Safety Glove Accessories

In addition to quality rubber insulating gloves, Burlington Safety Laboratory offers a variety of accessories, including:

In addition to quality rubber insulating gloves, Burlington Safety Laboratory offers a variety of accessories, including:

- Leather Protectors: Leather protectors are made to be worn over rubber insulating gloves to provide protection against cuts, abrasions and punctures.

- Rubber Insulating Sleeves: These provide added protection from the end of the glove to the shoulder to prevent accidental contact with charged equipment and cables.

- Storage Bags: Canvas storage bags provide an added layer of protection for rubber gloves and sleeves protecting them from the elements therefore improving their service life.

- Additional Accessories: Glove liners, glove dust, sleeve straps, rubber goods cleaner, etc.

Electrical Safety Gloves at Burlington Safety Laboratory

For more than 50 years, Burlington Safety Laboratory has been at the forefront of electrical safety testing and electrical PPE distribution. To learn more about our electrical safety gloves and accessories, visit our product page, or contact us today!