Ensuring Electrical Safety Across All Applications

In high voltage environments, safety isn’t just a best practice – it’s a critical requirement. From the vast networks of utility grids to the intricate systems within industrial facilities, managing high voltage electricity demands unwavering attention to safety protocols and the right equipment.

Burlington Safety Laboratories (BSL) stands as a trusted leader in providing comprehensive high voltage safety solutions. We don’t just supply the essential personal protective equipment (PPE) and tools; we also ensure their ongoing integrity through expert testing services, helping you meet and exceed demanding industry standards.

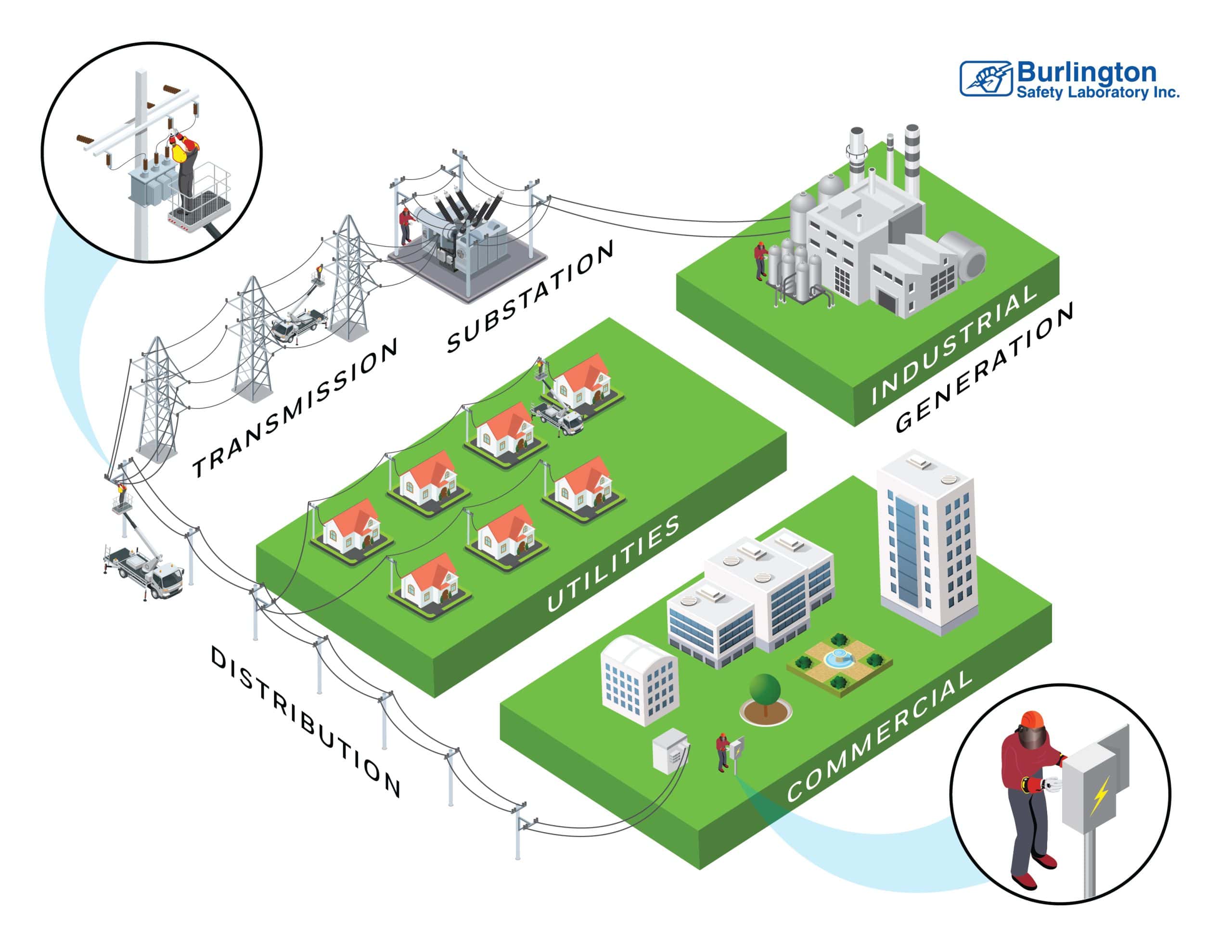

Electrical hazards can manifest differently across various environments. BSL understands these nuances and offers tailored solutions for:

Utility Applications: Powering Communities Safely

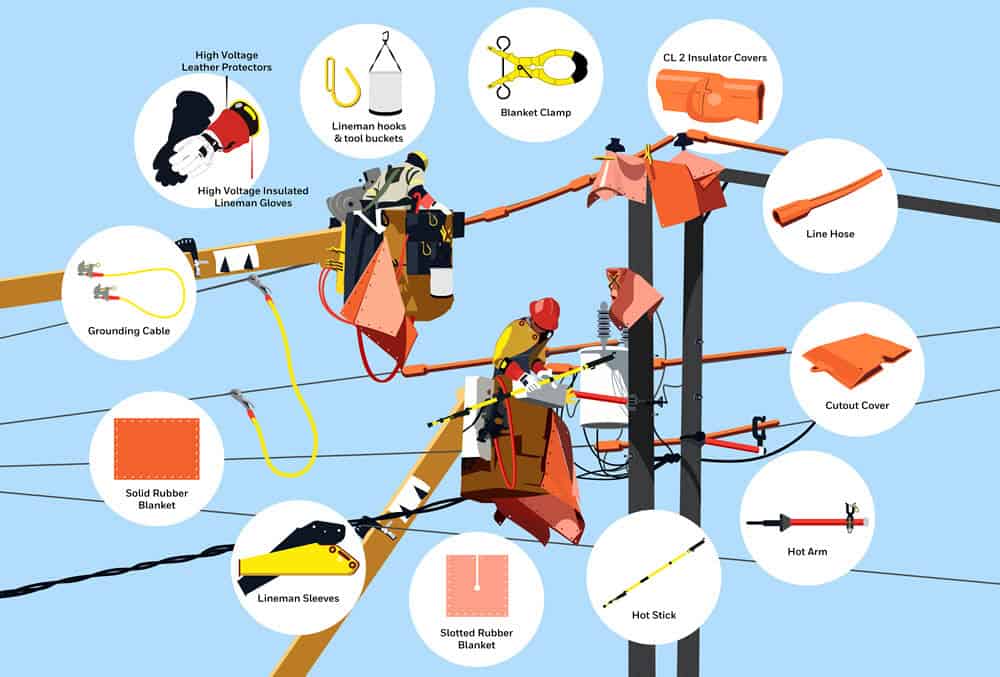

The backbone of our utilities infrastructure is the workers (linemen) who operate in extremely high-voltage environments, often outdoors and exposed to various elements. Their work, ranging from transmission lines and substations to distribution networks, requires specialized equipment designed for ultimate protection and durability.

Safety Demands in Utility Applications:

- Extreme High Voltage Protection: Protection against arcs, shocks, and flashovers from tens of thousands of volts.

- Outdoor Durability: Equipment must withstand diverse weather conditions and rigorous use.

- Live-Line Work Capabilities: Tools and PPE for safely working on energized lines.

- Comprehensive Grounding: Procedures and equipment to ensure circuits are de-energized and grounded.

BSL provides a full spectrum of high voltage safety equipment crucial for linemen crews, including:

- High Voltage Insulated Lineman Gloves & Leather Protectors: Essential for protection against electrical shock.

- Lineman Sleeves: Additional arm protection for high voltage work.

- Solid & Slotted Rubber Blankets, Line Hoses, CL. 2 Insulator Covers, Cutout Covers: Insulating barriers to prevent accidental contact with energized components.

- Grounding Cables: For reliable de-energization and grounding of circuits.

- Hot Sticks & Hot Arms: Insulated tools for manipulating energized lines from a safe distance.

- Lineman Hooks & Tool Buckets, Blanket Clamps: Specialized accessories for efficient and safe work practices.

Industrial Applications: Protecting Complex Operations

Industrial environments, including manufacturing plants, processing facilities, and large-scale generators, often feature complex electrical systems with significant power demands. Safety in these settings is paramount to protect personnel and ensure uninterrupted operations.

Safety Demands in Industrial Applications:

- Arc Flash Protection: Comprehensive PPE to guard against severe burns and injuries from arc flash incidents.

- Electrical Shock Prevention: Insulated tools and protective gear to prevent direct contact with energized parts.

- Lockout/Tagout Support: Equipment and procedures for safely de-energizing machinery during maintenance.

- Emergency Response: Tools for quick and safe rescue in electrical incidents.

BSL offers robust solutions tailored for the demanding nature of industrial electrical work:

- Arc Flash Kits, Arc Flash Hoods & Coveralls: Head-to-toe protection designed to withstand the intense heat and energy of an arc flash.

- High Voltage Insulated Lineman Gloves & Leather Protectors: Critical for hands-on work with energized equipment.

- Face Shields & Dielectric Footwear: Additional layers of protection for the head and feet against electrical hazards.

- Insulated Hand Tools: Tools with non-conductive handles, crucial for working on live electrical components.

- Rescue Hooks & Static Discharge Sticks: Essential for safely removing individuals from electrical contact and discharging residual energy.

- Arc Suppression Blankets: Used to contain or suppress arc flash energy.

- Electrician’s Tool Bags: Durable and organized storage for safety tools.

Commercial Applications & General Facility Maintenance

From office buildings and retail spaces to hospitals and educational institutions, commercial facilities rely heavily on stable electrical power. Regular maintenance and unforeseen issues require trained personnel to safely interact with electrical panels, wiring, and equipment.

Safety Demands in Commercial & Facility Maintenance:

- Basic Electrical Hazard Protection: Protection against common electrical shocks and minor arc flashes.

- Safe Maintenance Practices: Equipment for routine inspections, repairs, and installations.

- Portability & Versatility: Tools and PPE that are easily transportable for various maintenance tasks across a facility.

- Compliance with OSHA & NFPA 70E: Adherence to established safety standards for general electrical work.

BSL supports commercial and general facility maintenance with essential safety equipment that ensures workers are protected during everyday electrical tasks:

- High Voltage Insulated Lineman Gloves & Leather Protectors: Fundamental for any interaction with electrical systems.

- Face Shields & Dielectric Footwear: Providing crucial personal protection.

- Insulated Hand Tools: Preventing accidental electrical contact during repairs and installations.

- Arc Flash Kits & Arc Flash Hoods: Even in lower voltage commercial settings, arc flash remains a significant risk requiring proper protection.

- Rescue Hooks: A vital safety tool for any facility where electrical work is performed.

- Electrician’s Tool Bags: Keeping essential safety tools organized and accessible for on-the-go maintenance.

Beyond Sales: BSL’s Comprehensive Product Testing Services

Providing high-quality safety equipment is only half the equation. The effectiveness of electrical safety gear, especially rubber insulating products, diminishes over time and with use. Industry standards, such as those dictated by ASME, require regular testing intervals to ensure ongoing safety and compliance.

Providing high-quality safety equipment is only half the equation. The effectiveness of electrical safety gear, especially rubber insulating products, diminishes over time and with use. Industry standards, such as those dictated by ASME, require regular testing intervals to ensure ongoing safety and compliance.

BSL’s Commitment to Your Safety Continues with Expert Testing:

We are not just a supplier; Burlington Safety Laboratories is also a fully equipped and certified testing facility. We provide crucial testing services for your high voltage rubber electrical safety gloves, blankets, sleeves, and other dielectric equipment. Our rigorous testing procedures adhere strictly to required standards, ensuring your equipment remains safe, compliant, and ready for service.

Why Regular Testing is Non-Negotiable:

- Compliance: Meet regulatory and industry mandates (e.g., OSHA, ASTM, NFPA 70E).

- Worker Safety: Ensure the integrity and effectiveness of critical PPE.

- Risk Mitigation: Reduce the likelihood of electrical accidents and associated liabilities.

- Equipment Longevity: Identify and address issues before they lead to equipment failure.

Partner with Burlington Safety Laboratories

At Burlington Safety Laboratories, we are dedicated to fostering a culture of safety wherever high voltage electricity is present. Whether you need to equip your utility crews, safeguard your industrial operations, or ensure the safety of your facility maintenance teams, BSL is your trusted partner.

Contact us today to discuss your specific safety equipment needs or to schedule your required product testing.